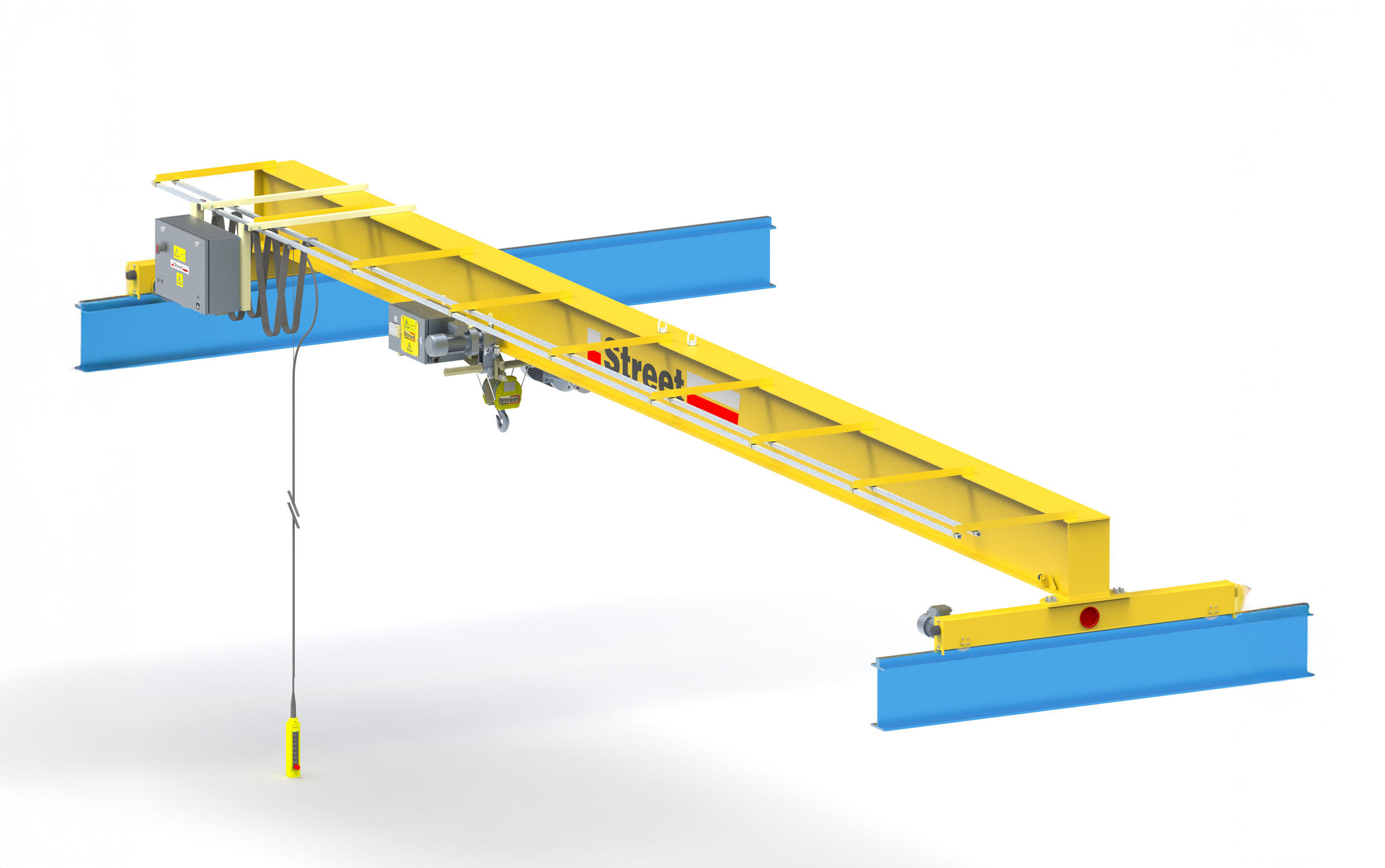

Single Girder Crane

Single Girder Cranes: Our Most Popular Overhead Lifting Solution.

Single Girder Cranes are our most popular type of overhead crane. Street single girder cranes are a practical, cost-effective way to cover everyday lifting duties up to 25 tonnes, indoors or outdoors. The single girder layout typically brings lower wheel loads, which can reduce runway and structural demands and improve the overall price-to-performance of the installation.

Where the application calls for higher capacity or more demanding duty, we specify our ZX wire rope hoist technology, engineered for long-term reliability and reduced maintenance through features such as a braked gearbox, enclosed oil-immersed gearing and a trolley design that eliminates external gears and wheel flange wear. For very low capacities, or where a compact and competitive solution is the right fit, we can also supply LX single girder top-running cranes up to 5 tonnes using an electric chain hoist.

Why choose a Street single girder crane?

Trust Street Crane to provide reliable single girder cranes that meet your specific needs and enhance your operational efficiency.

Built for performance and longevity

A single girder crane should do more than lift safely on day one. It should stay accurate, dependable and straightforward to service for years. That is why our ZX single girder cranes are designed with lifetime cost of ownership in mind, including an open, service-friendly layout and built-in protection and monitoring to support planned maintenance and reduce unplanned downtime.

As a family-run engineering business with 80 years of lifting expertise, we work closely with your operations, maintenance and procurement teams to specify a solution that suits your building, your duty cycle and your long-term site strategy.

Hoist options for your application

We match the hoist to your lift, not the other way round:

- ZX Electric Wire Rope Hoist (single girder up to 25 tonnes): braked gearbox design, enclosed oil-immersed gearing and wear-reducing trolley guidance for demanding industrial use and long-term maintainability.

- LX Electric Chain Hoist (single girder up to 5 tonnes): a compact, cost-effective option for lighter duties, with efficient use of space and flexible operation by pendant or radio control.

If you are planning a new crane, a replacement, or a capacity upgrade, we are here to help you specify it with confidence. Call our experts today.

Built for performance and longevity

Single Girder Cranes FAQs

What is a top running Single Girder Crane, and where is it typically used?

A top running single girder crane is an overhead travelling crane that runs on runway rails and uses one main beam (girder) to carry the hoist and trolley. It’s a popular, practical choice across general industry because it delivers dependable handling without overcomplicating the crane structure.

Single girder cranes are commonly specified for workshops, fabrication, general manufacturing and multi-crane environments, where you want efficient coverage, straightforward operation and sensible lifecycle costs. They can also be engineered for outdoor use, provided the specification reflects exposure, corrosion risk, temperature, wind considerations, duty cycle and maintenance access.

What capacities are available, and how do ZX and LX fit into the range?

Street’s top running single girder range covers all capacities up to 25 tonnes with ZX electric wire rope hoists, and up to 5 tonnes with LX electric chain hoists where a compact, extra-competitive solution is the right fit.

In simple terms, ZX is typically chosen where the duty is more demanding, lifts are higher, or the capacity and performance requirements point towards wire rope. LX is often ideal for lower capacities and lighter duty where simplicity and value are key. We’ll always match the hoist to your real duty cycle and working envelope, not just the headline capacity.

Why are Street Single Girder Cranes considered cost-effective?

Single girder cranes are often cost-effective because the layout typically produces lower wheel loads, which can reduce structural and runway support requirements. That can mean lower overall building costs, especially in retrofit projects or where runway steelwork drives the budget.

Just as importantly, Street’s approach is to improve value through lifetime cost of ownership. The aim is fewer wear points, easier inspection, and maintenance tasks that can be planned and completed efficiently, reducing downtime risk and long-term cost.

What makes Street ZX hoists different mechanically?

ZX technology is engineered to remove common wear points and improve service access. The key elements work together:

- A braked gearbox hoist design improves load security and maintainability. The brake holds the load even if the hoist motor is removed, or if motor-side components (coupling, shaft, connection) were to fail. It also avoids brake heat soaking into the motor and improves brake accessibility.

- No external hoist gears: hardened, precision-ground helical gears running submerged in oil, reducing contamination and extending gear life versus exposed gearing.

- No external trolley gears: direct drive travel with enclosed, oil-immersed gearing, avoiding external gears cut into wheel flanges.

- Guide rollers with flangeless wheels: reduces wheel and beam flange wear, lowers rolling resistance and improves trolley control and stability.

- A reaction roller can remove the need for a counterweight in low headroom single girder arrangements, reducing hoist/crane weight and improving traction and control.

All of this is aimed at the same outcome: reliable performance you can maintain sensibly over the long term.

What control options are available, and when should we specify VFD-based advanced control?

Single girder cranes can be supplied with a choice of travel control approaches, including traditional two-speed control and advanced control using Variable Frequency Drives (VFDs). VFD-based control is typically worth specifying where you need:

- Smooth acceleration and deceleration to protect loads, tooling and structures

- Predictable stopping and repeatable positioning

- Better handling confidence in busy bays or where precise placement matters

- Diagnostic insight that supports planned maintenance

Where VFD-based advanced control is chosen, we can tailor speed profiles to the process, and combine that with controlled braking to suit your application.

What safety, braking and load protection features are built in?

ZX hoists can include several proven features that support safe, controlled handling:

- A heavy duty double band rope guide designed to manage slack rope risk and guide the rope consistently into the drum scroll.

- A patented safe load cut-out device located at the hoist gearbox torque arm, actuated directly by load rather than relying on electrical current measurement alone.

- Adjustable DC disc brakes on travel and traverse to tune stopping distances to the application.

- Built-in electrical protection and monitoring, including hoist motor overheat protection, hours-in-service metering, phase failure/incorrect phase sequencing protection, and under-voltage/over-current protection.

The result is a crane that’s not only safe in principle, but engineered to behave predictably in daily use.

How do Street single girder cranes help reduce downtime and maintenance effort?

Downtime reduction comes from two places: removing common failure points and making service faster. ZX is designed to do both, using enclosed gearing, reduced wear interfaces (guide rollers), service-friendly access features (including inspection covers and motor coupling viewing access), and clear electrical protection/monitoring.

For procurement, this supports a lower lifetime cost and reduced operational disruption. For engineers, it means fewer awkward strip-down tasks and more straightforward planned maintenance.

What do you need from us to size and specify a Single Girder Crane correctly, and what’s the first step?

To specify correctly, we typically need: SWL, span, runway length, headroom and required hook approach, duty cycle/classification, load characteristics, control preference, power supply and environmental conditions (including whether it’s indoor or outdoor).

The fastest first step is to share your capacity, span, runway length, headroom constraints, duty cycle and preferred control method. If you have a layout drawing or photos, it helps us move quickly and avoid assumptions, so you get a solution that fits the building and the job from day one.

Our Global Distributor Network

Street Crane products are available globally through a network of official distributors.

View our Distributor NetworkGet Started Today

Have any questions or want a quote please contact us