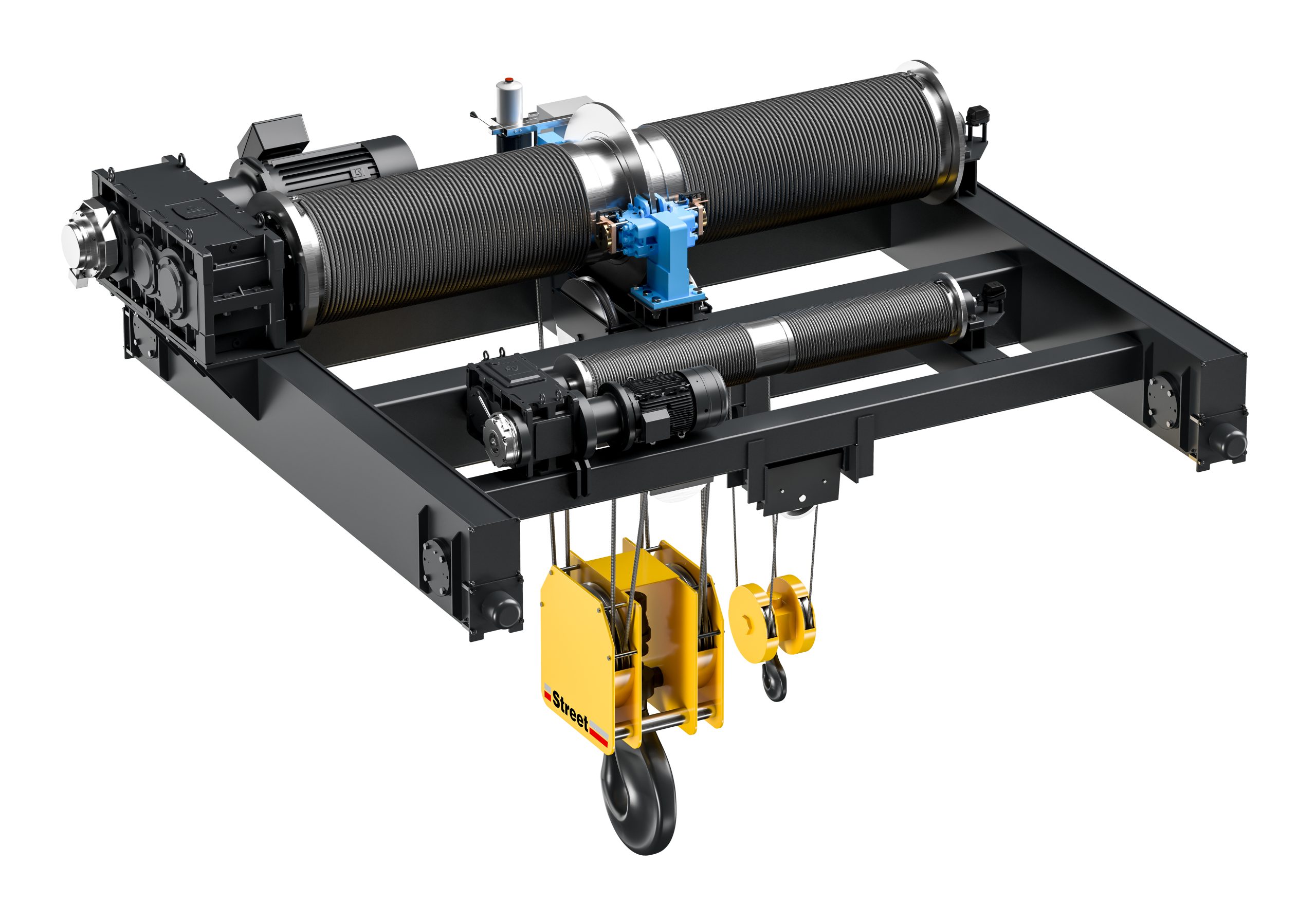

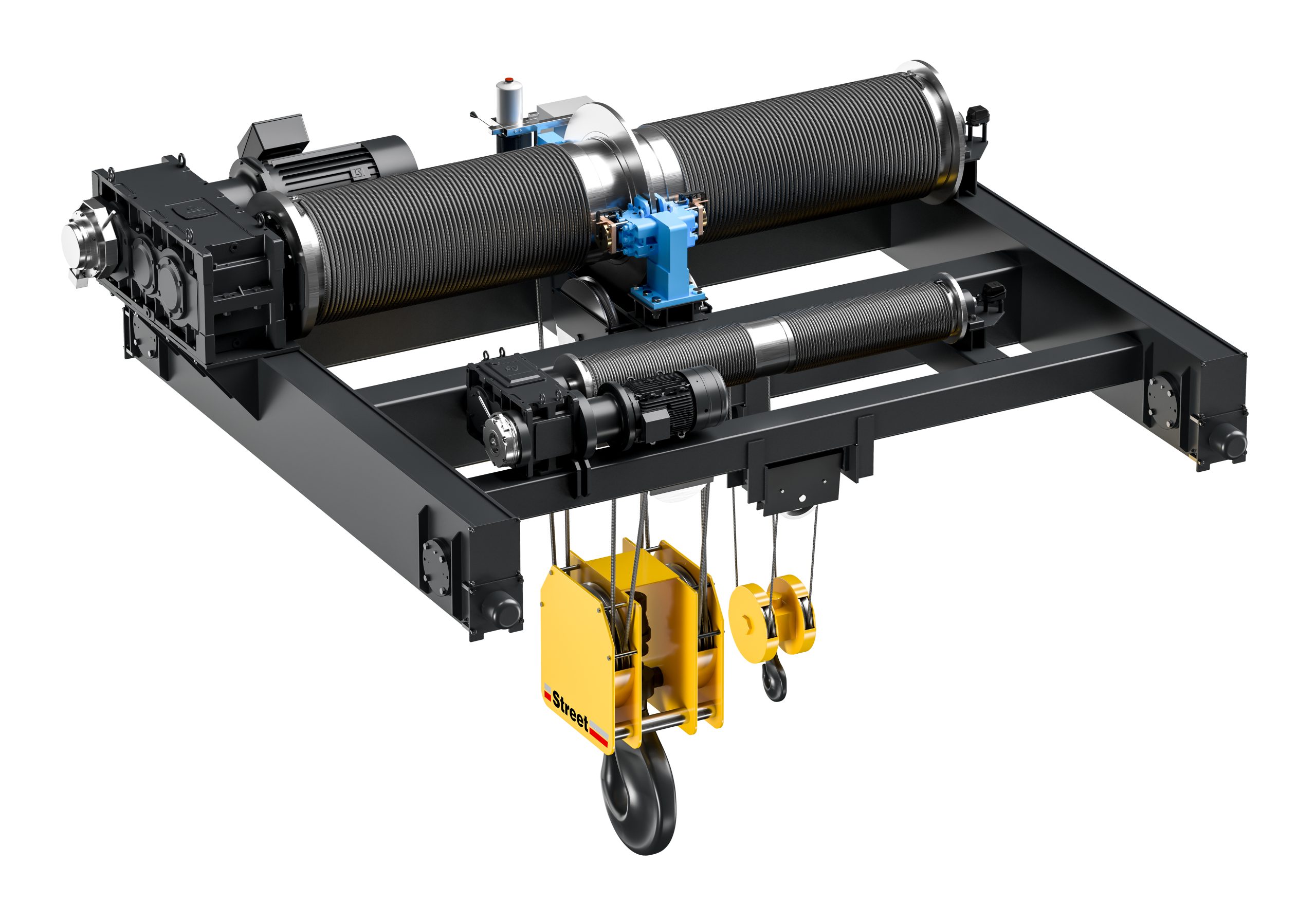

Open Winch Hoists (VX)

Choose the VX Hoist for Your Most Demanding Lifting Applications.

Every industry requires something different and special processes often require additional equipment, features or safety mechanisms. If your application requires something more demanding, our VX open winch hoist is the perfect solution and combines the latest innovations in control systems with traditional heavy-duty engineering.

The rugged design of the VX has a proven pedigree and excels where customer specifications require a unique heavy-duty lifting solution.

VX open winch hoist key features

The VX Range

VX: Custom Engineered to Suit Your Lifting Application.

Street Crane has more than seven decades of experience designing and manufacturing hoists for the more extreme applications. The VX hoist is a product of that pedigree and epitomises the special performance levels we can offer those customers who have the most exacting requirements. The VX hoist is a modular concept which uses pre-engineered components in both standard and customised formats to provide high-performance and high-reliability for a very wide range of demanding applications where one or more of the following are required:

- Capacities up to 250 tonnes (275 US Tons).

- Duty classifications up to ISO M8/CMAA CLASS F.

- Superfast hoisting speeds.

- Super-high lifts.

- Increased factors of safety.

- Extremely arduous environments.

- Additional safety and operating equipment.

Special hoist constructions.

The VX Range

Get Started Today

Have any questions or want a quote please contact us