Specialised Hoists for Industrial Applications

Lifting capacities up to 250 tonnes

Tailored Designs to Perfectly Suit Your Requirements.

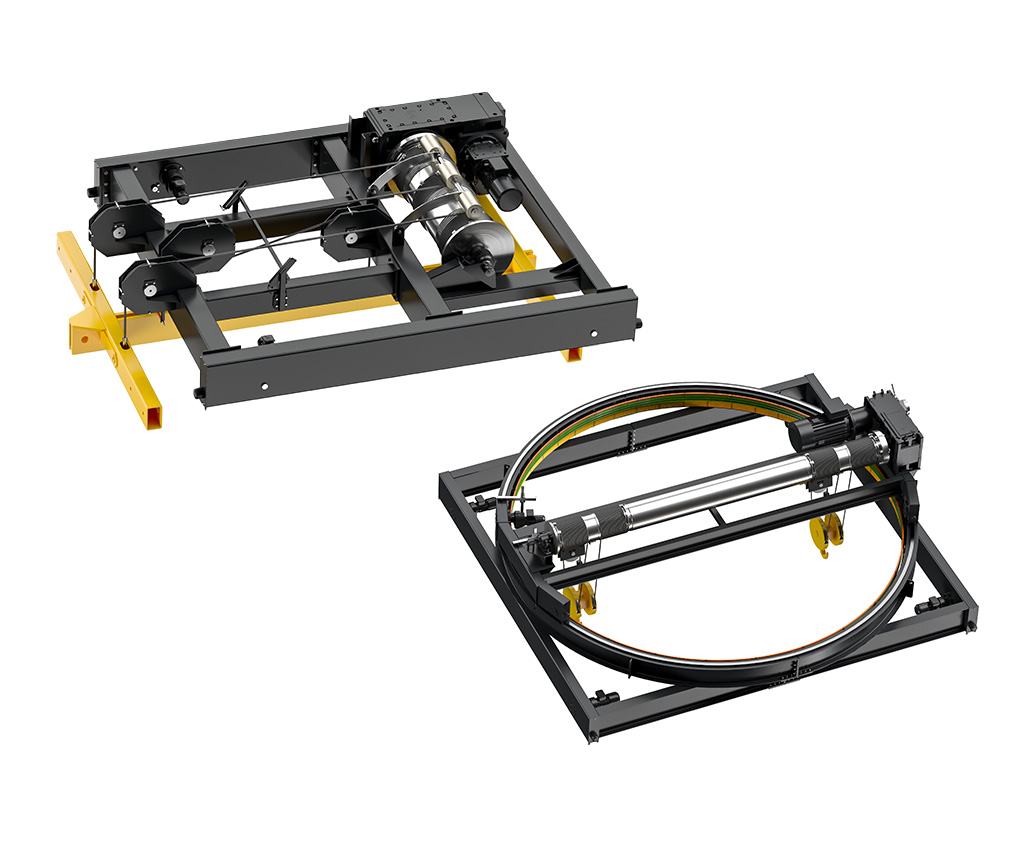

Street is one of a very few companies worldwide with the capability to employ software programmes to design truly bespoke wire rope hoists based on modular parts or from first principles. Many of the world’s leading crane makers incorporate Street special hoists into their crane designs. Engineered hoists can incorporate the most advanced control and monitoring systems or the most traditional heavy duty engineering or a combination of both.

Specialised hoist key features

Throughput and duty performance

For high-output processes, special hoists can be engineered for extra-fast speeds and arduous duty combinations where heat, wear and stopping performance are critical. VFD-based control can also support regenerative braking and functions such as Load Dependent Speed (LDS) helping maintain consistent cycle times without compromising control.

High lifts and engineered reeving

Where lift height is the constraint, we can design for extra-large lifting heights and specialist reeving arrangements. This includes twin hoists roped into a single bottom block and hook for super high lifts, with additional protection such as a bottom-block operated over-hoisting limit switch alongside the standard rotary limit.

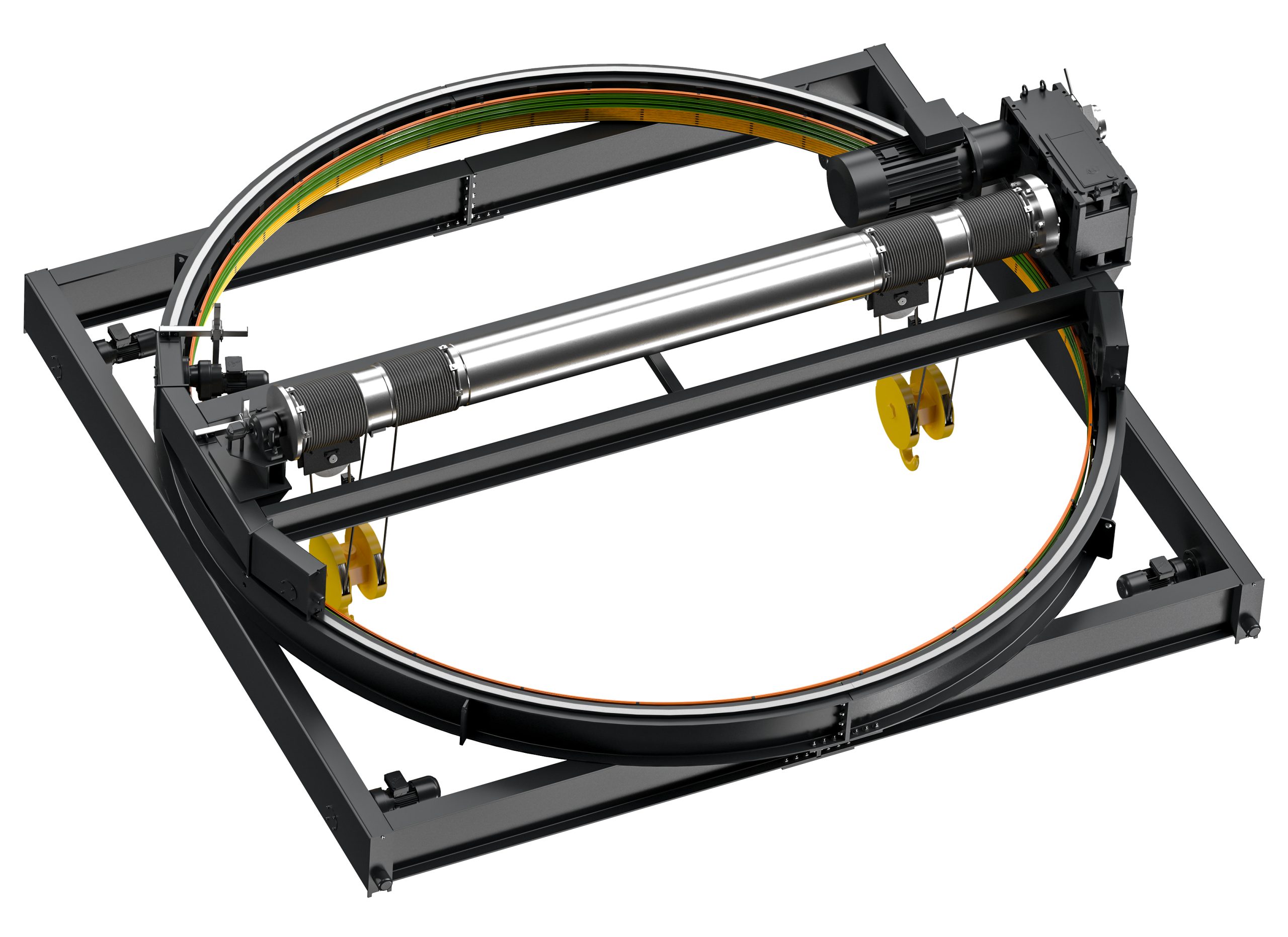

Synchronised and specialist load handling

When alignment, stability or handling method drives the design, we engineer multiple synchronised hoists or multi-point lifting from a single hoist. We can integrate grabs and lifting devices, and incorporate power slewing in the hoist frame or hook block to support controlled positioning for specialist handling tasks. Where travel-induced load movement is a risk, anti-sway control can be applied to reduce hook swing caused by traverse motion.

Safety-critical and fail-safe operation

For safety-critical applications, we engineer risk reduction into the mechanical system and the control strategy. Options include a second brake on the hoist motor for primary brake failure, a second brake acting on the hoist drum for over-speed scenarios, and safe torque off on VFD hoists where appropriate. Slack-rope detection and prevention can be included to protect against unsafe rope conditions during operation. For the highest consequence lifts, a mechanically failsafe load arrestor can provide independent overspeed and overload protection, with optional load recovery capability for nuclear applications.

Control, monitoring and harsh conditions

Special hoists often need enhanced operational visibility and resilience, especially in extreme environments or continuous duty. We can provide remote control with optional LCD status display, micro-speed hoisting and lowering for precision placement, and condition monitoring including Design Working Period (DWP) tracking. Designs can be specified for non-standard ambient temperatures from -20°C to +70°C, and adapted for hazardous loads such as molten metal.

Get Started Today

Have any questions or want a quote please contact us