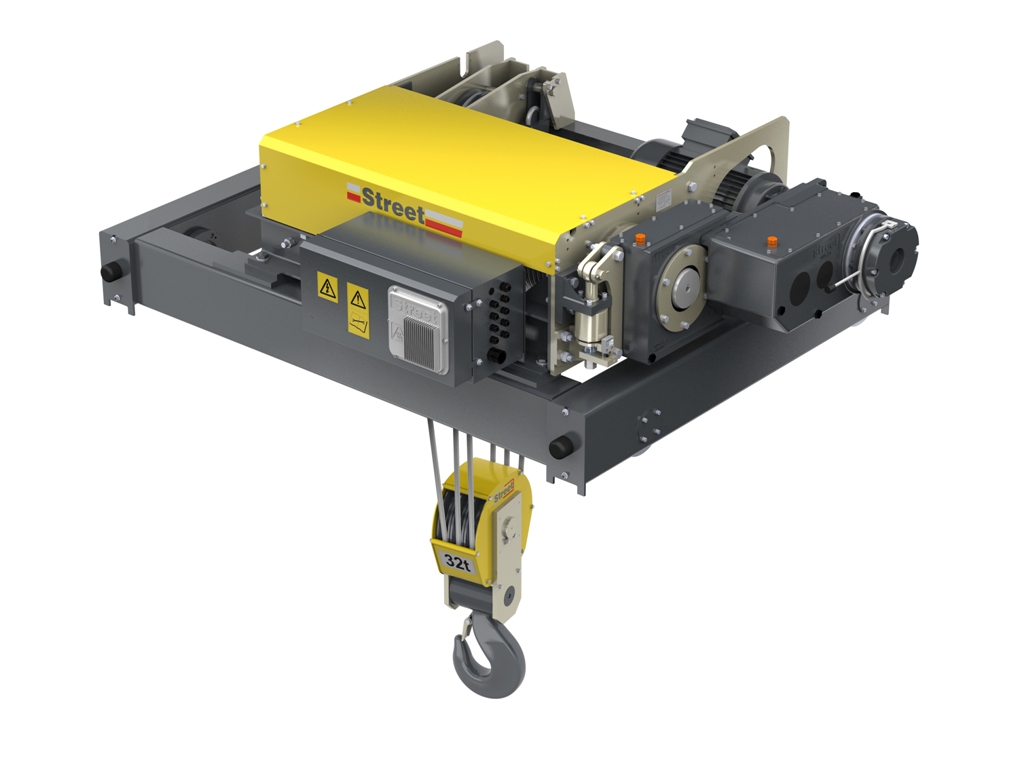

Electric Wire Rope Hoists (ZX)

The Street ZX Hoist: Our All-Purpose Workhorse with Genuine Differences.

The first generation Street ZX electric wire rope hoist was first developed in the late 1990s and very quickly became the best selling hoist product that Street has ever produced, firmly establishing us as a global hoist manufacturer. The unique design developed a strong reputation for reliability and endurance, with an unparalleled record in a vast range of applications and environments worldwide.

Every function of our latest generation ZX hoist has been reviewed and a whole series of innovations applied to provide new levels of user-friendliness and performance. The result is an easy to operate, high endurance hoist incorporating state-of-the-art technology.

ZX hoist key features

The ZX Range

The ZX Range

Get Started Today

Have any questions or want to get a quote contact us now.