Automotive Plant Cranes

Industry Applications

Safe, Precise, and Efficient Lifting for Automotive Manufacturers

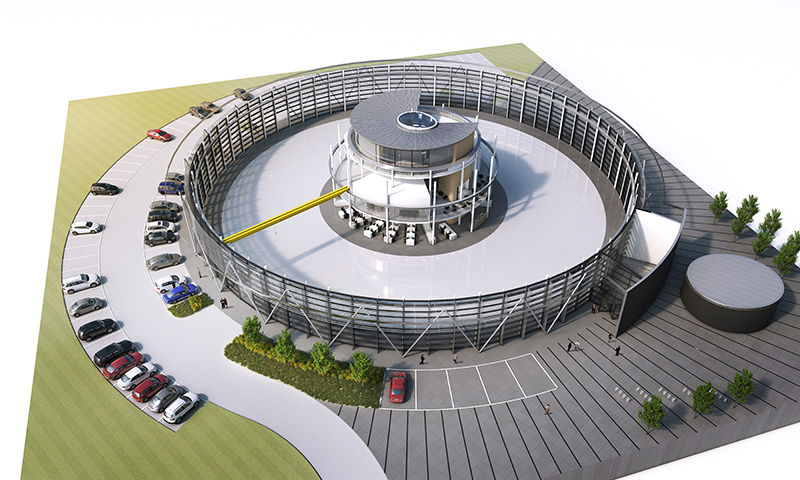

Automotive manufacturers demand safe, precise, and efficient lifting and handling solutions, often utilising semi-automated technologies. Street Crane has delivered these solutions globally, including press plant cranes for the efficient storage and retrieval of heavy dies used in vehicle body panel production.

Our cranes feature market-leading ZX electric wire rope hoists, with capacities up to 60 tonnes, and offer precise turning operations and automated product placement controls.

Some of the products and features we have supplied to the automotive sector.

- Twin Hoists with Load Summation: Twin hoists are designed to work in tandem, ensuring balanced lifting and precise load handling. The load summation feature allows for the combined weight of the load to be accurately measured and distributed between the hoists, enhancing safety and efficiency.

- Secondary Braking and Load Arrestors: These systems provide an additional layer of safety by ensuring that loads are securely held in place even in the event of primary brake failure. Load arrestors act as a fail-safe mechanism, preventing uncontrolled descent and potential accidents.

- Overspeed Protection: This feature safeguards against the dangers of excessive speeds in lifting operations. By monitoring and controlling the speed of the hoist, overspeed protection helps prevent mechanical failures and enhances operational safety.

- Safety Rated Controls: Controls comply with stringent safety standards ensuring high reliability and performance designed to handle high-risk applications with a high degree of fault tolerance.

- Load Dependent Speed: This feature adjusts the speed of the hoist based on the weight of the load being lifted. By optimizing the lifting speed according to the load, it enhances efficiency and reduces wear and tear on the equipment.

- Design Working Period (DWP) Monitors: DWP monitors track the usage and operational life of lifting equipment. By monitoring the design working period, these devices help in planning maintenance schedules and ensuring the longevity and reliability of the equipment.

- Condition Monitoring: Condition monitoring systems continuously assess the health and performance of lifting equipment. By detecting potential issues early, these systems help in preventing unexpected breakdowns and ensuring smooth and safe operations.

- Micro-Speeds and Infinitely Variable Speeds: These features provide precise control over the lifting speed, allowing for smooth and accurate positioning of loads. Micro-speeds enable very slow movements for delicate operations, while infinitely variable speeds offer a wide range of speed adjustments to suit different lifting requirements.

See Our Previous Work

Get Started Today

Have any questions or want a quote please contact us