Metals & Steel Manufacturing Industry Cranes

Iron, Steel Aluminium and More…

Many businesses around the world rely on Street technology for the handling of ferrous and non-ferrous metals. Lifting and handling metals in various states places very high demands on cranes and hoists. Typically high speeds, extreme levels of equipment utilisation, high performance and high reliability are required, all under arduous and challenging ambient conditions. The Street heavy duty VX open hoists and range of standard and special high-performing cranes enable us to deliver reliable, cost-effective handling and lifting for metals industries.

Molten metal handling cranes

Specialised ladle handling cranes for transporting molten metals from a furnace to casting areas. Particular attention is paid to the unique safety issues with secondary braking systems, safety-rated controls, and other backup systems to comply with European standards.

Billet handling cranes

Billets of ferrous and non-ferrous metals can be transported from a continuous casting machine conveyor to the storage area or to a rolling mill. Again, safety is the primary consideration due to the incredibly high temperatures and weight of products being transported.

Coil handling cranes

VX open hoists provide a true vertical lift enabling steel coils to be placed precisely whilst eliminating any sideways drag. The hoist’s open frame design provides easy access to major components for servicing.

An external brake operating on the first gearbox shaft, away from the drive motor, remains cooler in use and is also more easily inspected and serviced.

Some of the products and features we have supplied to the metals energy sector.

- Wireless Communication: Enables seamless and efficient communication between crane components and operators.

- Condition Monitoring: Provides real-time data on the crane’s performance and health, allowing for predictive maintenance and reducing downtime.

- Backup Power Units: Ensure continuous operation during power outages, enhancing reliability and safety.

- Toughened Glass Cabins with Air Conditioning and Insulation: Provide a comfortable and safe working environment for operators, protecting them from harsh external conditions.

- Heat Shielding on Critical Components: Protects vital crane parts from extreme temperatures, ensuring longevity and reliable performance.

- Backup Hoist Drum Brakes: Offer an additional layer of safety by providing emergency braking capabilities.

- Backup Rope Reeving Systems: Ensure continued operation in case of primary rope system failure, enhancing safety and reliability.

- Auxiliary Hoists for Maintenance: Facilitate maintenance tasks by providing additional lifting capabilities.

- Heavy Duty Slewing Controls: Enable precise and robust control of crane rotation, essential for handling heavy loads.

- Heavy Duty End Carriages with Hardened Wheels: Provide durability and stability, ensuring smooth and reliable crane movement.

- Cooled Electric Cabinets: Maintain optimal temperatures for electrical components, preventing overheating and ensuring consistent performance.

- Multiple Hoist Attachments: Enhance the versatility of the crane, allowing it to handle various types of loads and tasks.

- Additional Platforms and Walkways for Servicing: Provide safe and convenient access for maintenance and inspection tasks, improving overall safety and efficiency.

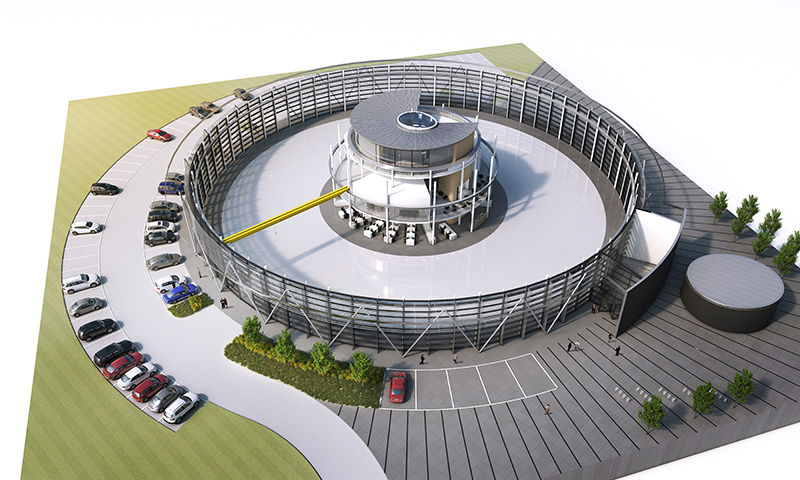

See Our Previous Work

Get Started Today

Have any questions or want a quote please contact us